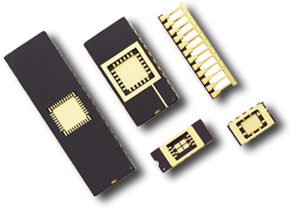

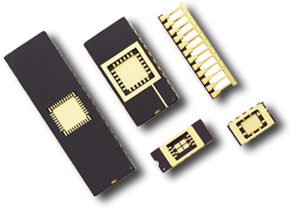

Leadless chip carrier sockets.

Ceramic leadless chip carrier socket.

A socket for a leadless chip carrier said socket including a base member having a central opening therein a plurality of conductive resilient contacts for engaging conductive pads on said carrier each contact anchored in said base member and including an upwardly extending part said contacts positioned on at least two side edges of said base member opening and constituting opposing.

Surface mount and soldertail options are available.

Castellations instead external leads.

28 44 52 68 84 and 124.

Stainless steel spring latch is available in a variety of thicknesses to facilitate proper contact.

Heat sinks also available in six sizes.

A plastic leaded chip carrier plcc has a rectangular plastic housing it is a reduced cost evolution of the ceramic leadless chip carrier clcc.

The chip is held into the socket by friction.

A premolded plcc was originally released in 1976 but did not see much market adoption.

The lcc package is preferred where requirements call out for a low profile package or a surface mountable solderable package with low inductance to be used in.

Kyocera s multilayer division utilizes the most state of the art equipment combined with a knowledgeable technical staff to create high quality durable leadless chip carriers lcc.

Prototypes and devices intended for extended temperature environments are typically packaged in ceramic while high volume products for consumer and commercial markets are typically packaged in plastic.

Socket or surface mount package.

28 44 52 68 84 and 124.

Ceramic leadless chip carrier lcc national does not assume any responsibility for use of any circuitry described no circuit patent licenses are implied and national reserves the right at any time without notice to change said circuitry and specifications.

Variety of body sizes.

Contact is primarily made on the sides of the package not the bottom in order to take advantage of the wiping action.

Leadless chip carrier sockets conform to jedec standards a b c and d.

Solder glass or epoxy seal.

A leadless chip carrier lcc has no leads but instead has rounded pins through the edges of the ceramic or molded plastic package.

Gold or solder dip.

Leadless chip carriers are ideal for surface mount applications.

Generally speaking sockets for plcc chips j lead are not compatible with leadless chip carriers since their contacts are typically recessed between fingers that align and grip the plcc package itself.

Stainless steel spring latch is available in a variety of thicknesses to facilitate proper contact force with the socket.

Heat sinks also available in six sizes.

Leadless chip carrier sockets conform to jedec standards a b c and d.

Surface mount and soldertail options are available.

Prototypes and devices intended for extended temperature environments are typically packaged in ceramic while high volume products for consumer and commercial markets are typically packaged in plastic.