Most engine builders will take full advantage of the coating by making jetting or computer timing and lighter weight oil for maximum power gains.

Ceramic coating engine internals.

These power enhancing coatings are intended for use with internal engine parts.

C lube dry film ceramic lubricant combines the durability of a ceramic resin with the lubricity of a ceramic lubricant.

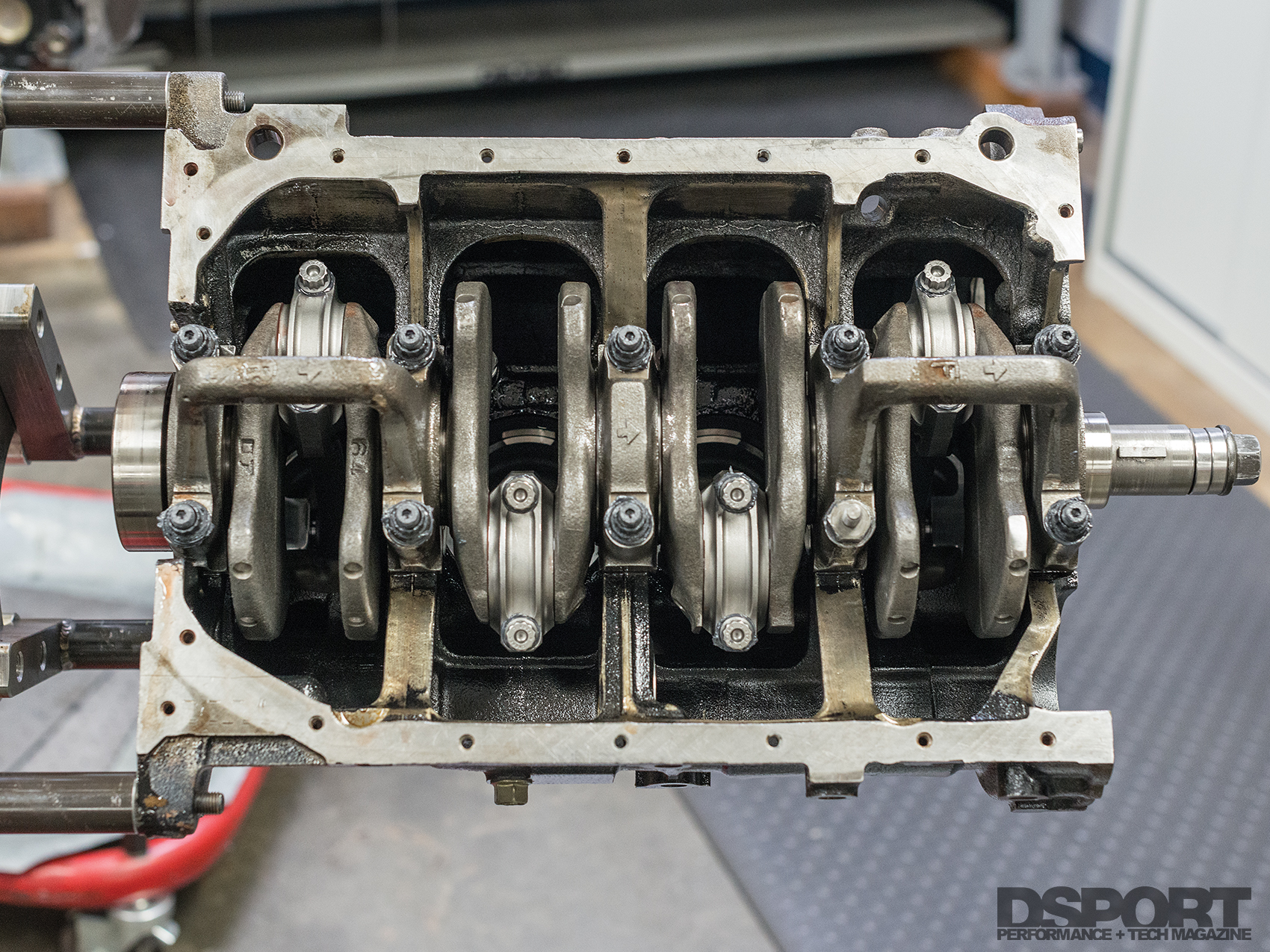

The skirts with the exclusion of the ring lands are coated with a ceramic dry film lubricant to guard against galling and.

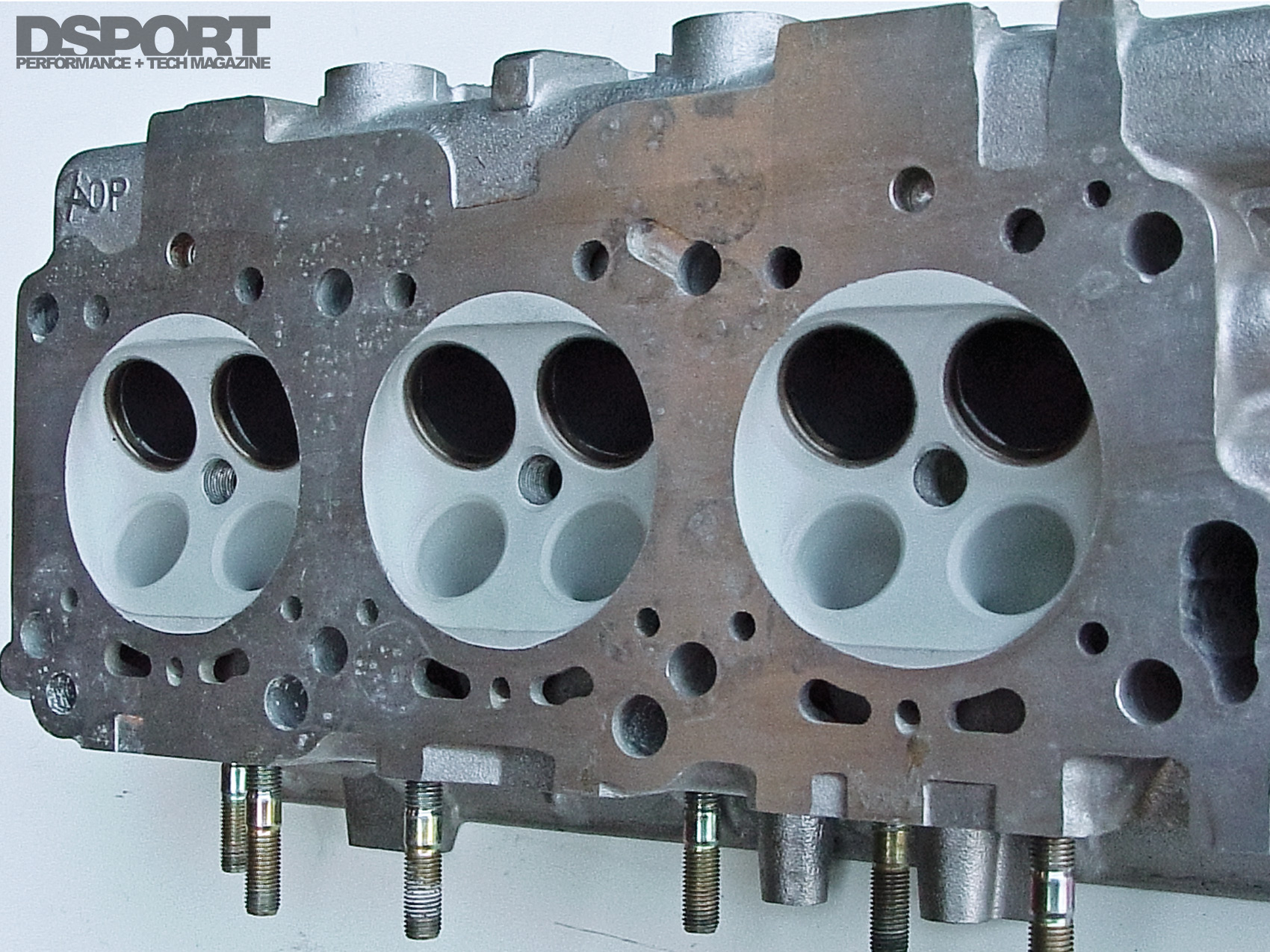

Dart coated most of the major internal engine parts for this story here a dart technician is coating the combustion chambers and exhaustports with dart s proprietary thermal barrier coatings.

The coating is also designed to aid in the more even transfer of heat reducing hot.

We also offer a more durable coating for engines using nitrous.

In addition to powder and ceramic coatings we also offer a full like of performance engine coatings.

Pistons we apply a ceramic barrier to the tops of the pistons to eliminate hot spots and to cause a faster and hotter burn.

However for this test we wanted to document and publish the gains that are achieved if the only modification was coating the engine.

A ceramic coating applied to a manifold or header will provide increased resistance to corrosion such as rust and lower the rate of heat loss resulting in greater power output.

C lube is a thermally cured dry film lubricant designed to provide high pressure lubrication to surfaces subject to sliding rotating or oscillating motion such as piston skirts and gears.

When applied to internal headers these coatings increase the speed of the exhaust gas and reduce overall turbulence by providing a smoother surface.