The present invention relates generally to electrochemical energy storage devices such as li ion batteries and more particularly to a method of providing uniform ceramic coatings with controlled thicknesses for separators in such storage devices.

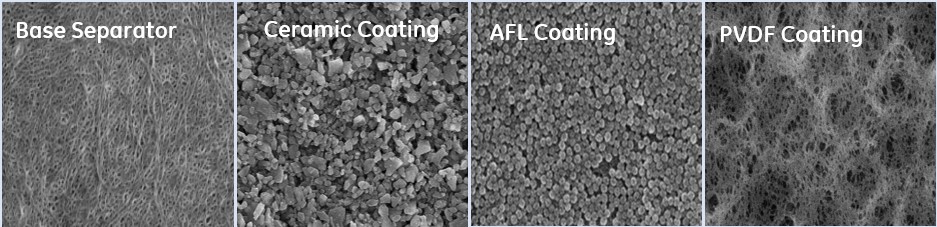

Ceramic coated separator.

Journal of materials science 2018 53 15 11038 11049.

Miltec patented uv ceramic coated separator chemistry miltec uv developed a revolutionary patented technology that gives lithium ion battery lib manufacturers the ability to deliver enhanced safety at a lower cost.

Enhancement of electrochemical performance of lithium ion battery by single ion conducting polymer addition in ceramic coated separator.

Those ceramic coated separators suffer less thermal shrinkage than the pristine separators but they still cannot meet the requirements for the safety of batteries because of their high shrinkage at high temperature due to the low melting point of binders.

The report gives the principle locale economic situations with the item value benefit limit generation supply request and market development rate and figure and so on.

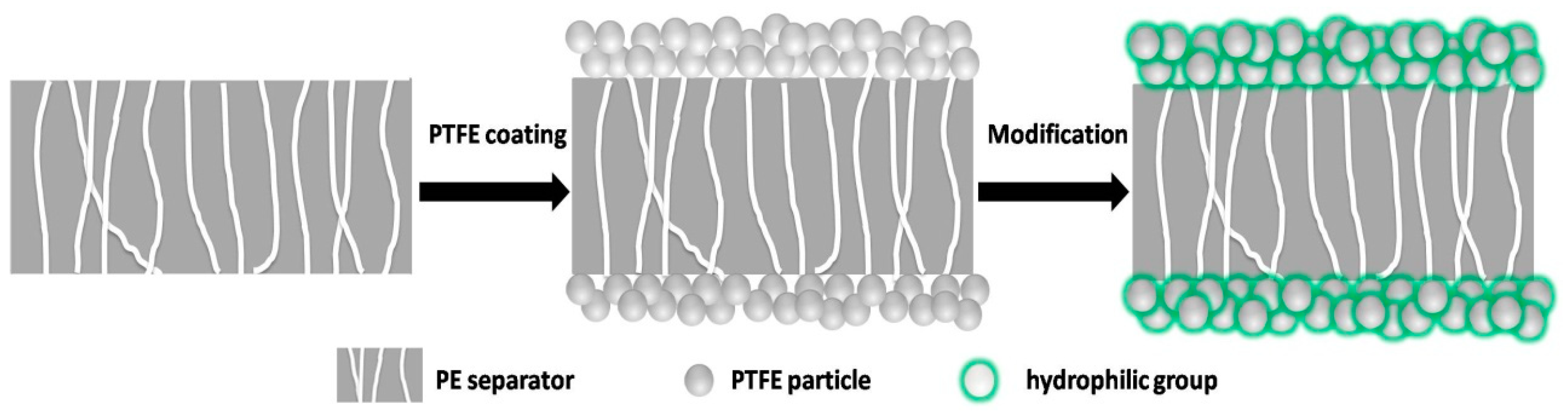

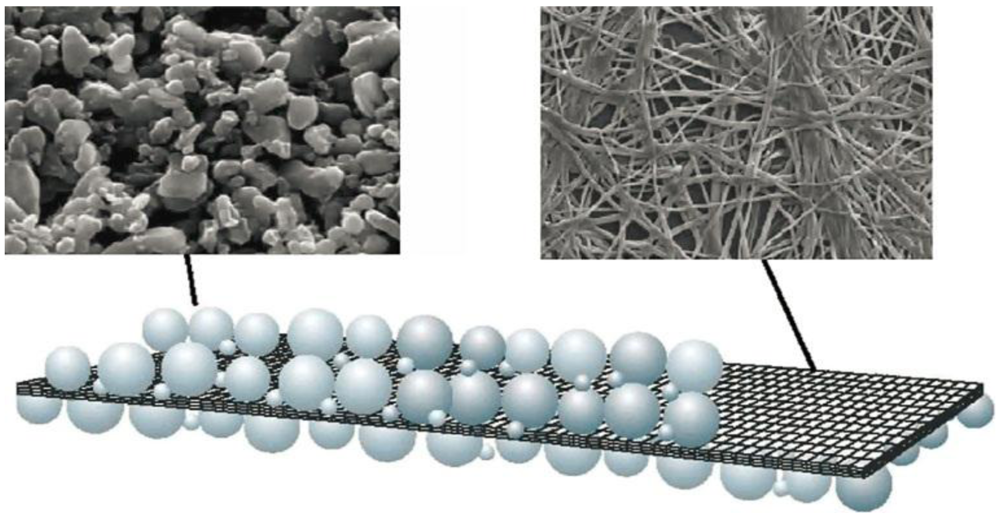

Some embodiments of the invention utilize a layer by layer coating of nano micro sized particles dispersed in a solvent which can be aqueous or non.

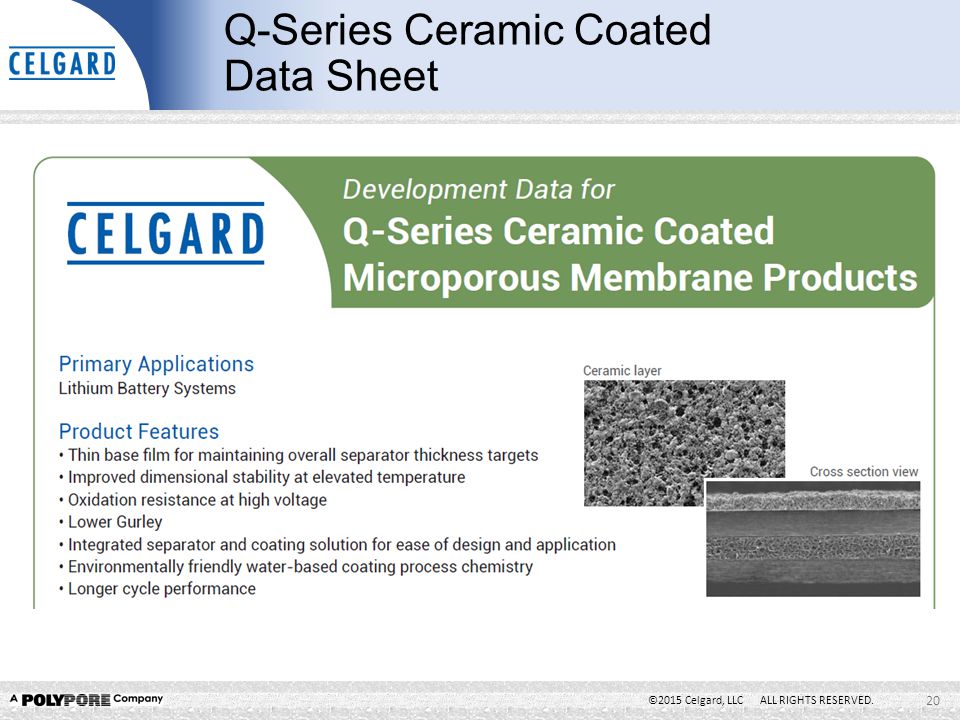

Ceramic coated separator nanopore ccs conventional lithium ion battery separators reinforced with a ceramic coating have demonstrated significant improvements to the safety cycle life and performance of lithium ion batteries libs leading to widespread industry adoption from smartphones to large format lithium ion batteries for electric vehicles xevs and other high energy or high.

Coated separator a 1 side 16 0 22 0 0 77 48 7 0 032 65 6 coated separator a 2 sides 15 2 18 9 0 76 45 9 0 031 65 5 coated separator b 2 sides 16 1 20 7 0 75 49 7 0 034 74 9 pore size distribution of base layer and ceramic coating can be differ entiated.

You may require a coated separator for low shrinkage low moisture content better adhesion increased life cycle or increased safety.

Ceramic coated separators eliminate many of the problems related to the usage of traditional separators the ceramic coating provides an electrically insulating layer that retains its physical integrity at high temperature allows for more efficient thermal heat transfer helps reduce thermal shrinkage and inhibits dendrite growth that could create a potential short circuit.

The fpes maintains nearly the same electrochemical performance as the commercial ceramic coated polyethylene separator cpes but significantly decrease the shutdown temperature of separator from 135 c to 110 c.

Secondly the coating layers are easy to desquamate from the porous polyolefin separator.

Finally ceramic coated separator market report is the believable source for gaining the market research that will exponentially accelerate your business.